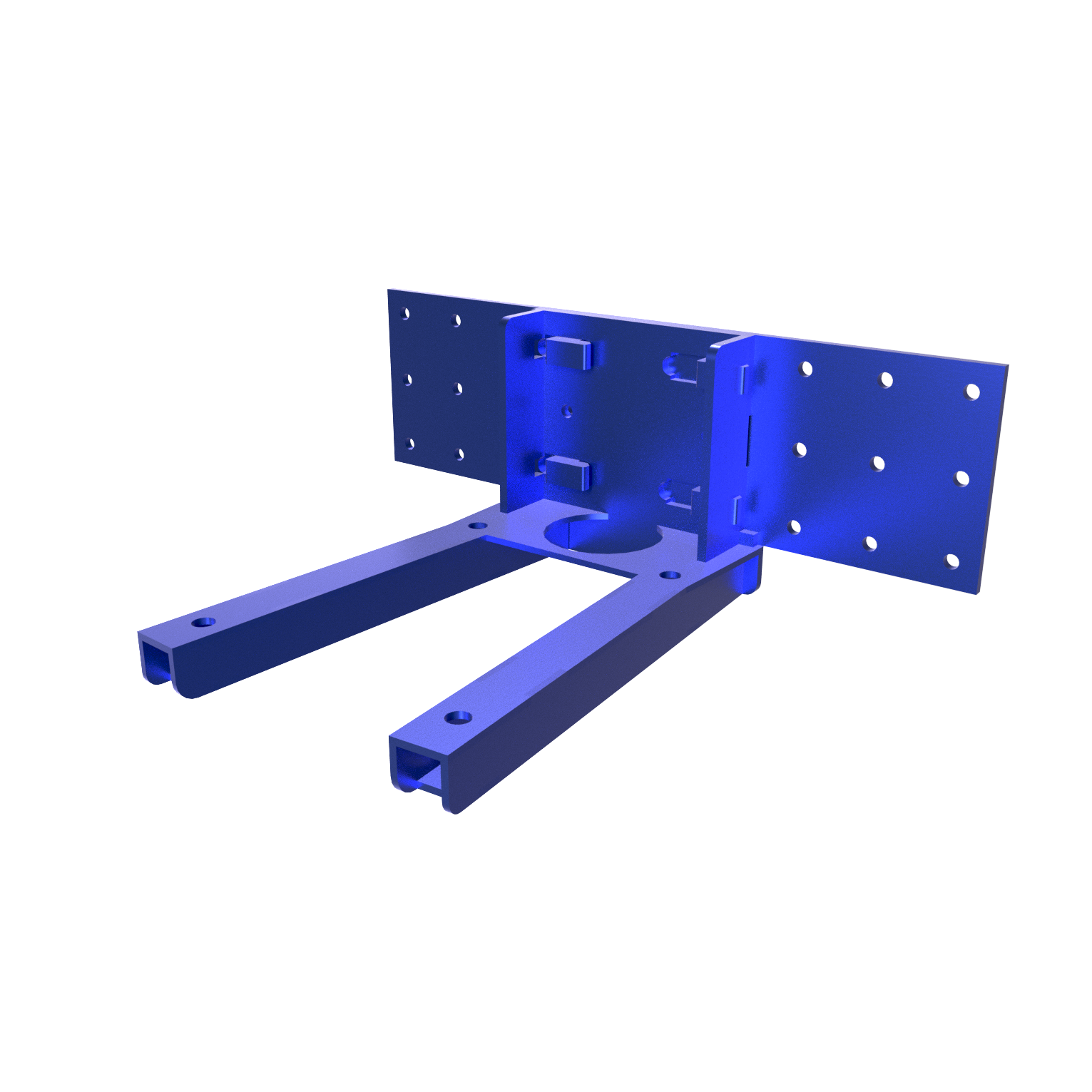

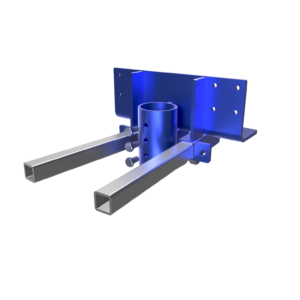

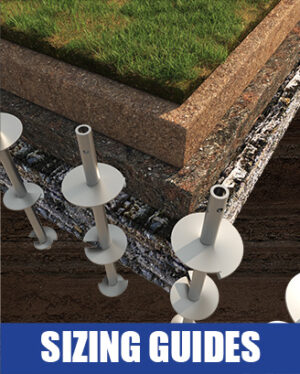

MP1018 Micropile Bracket

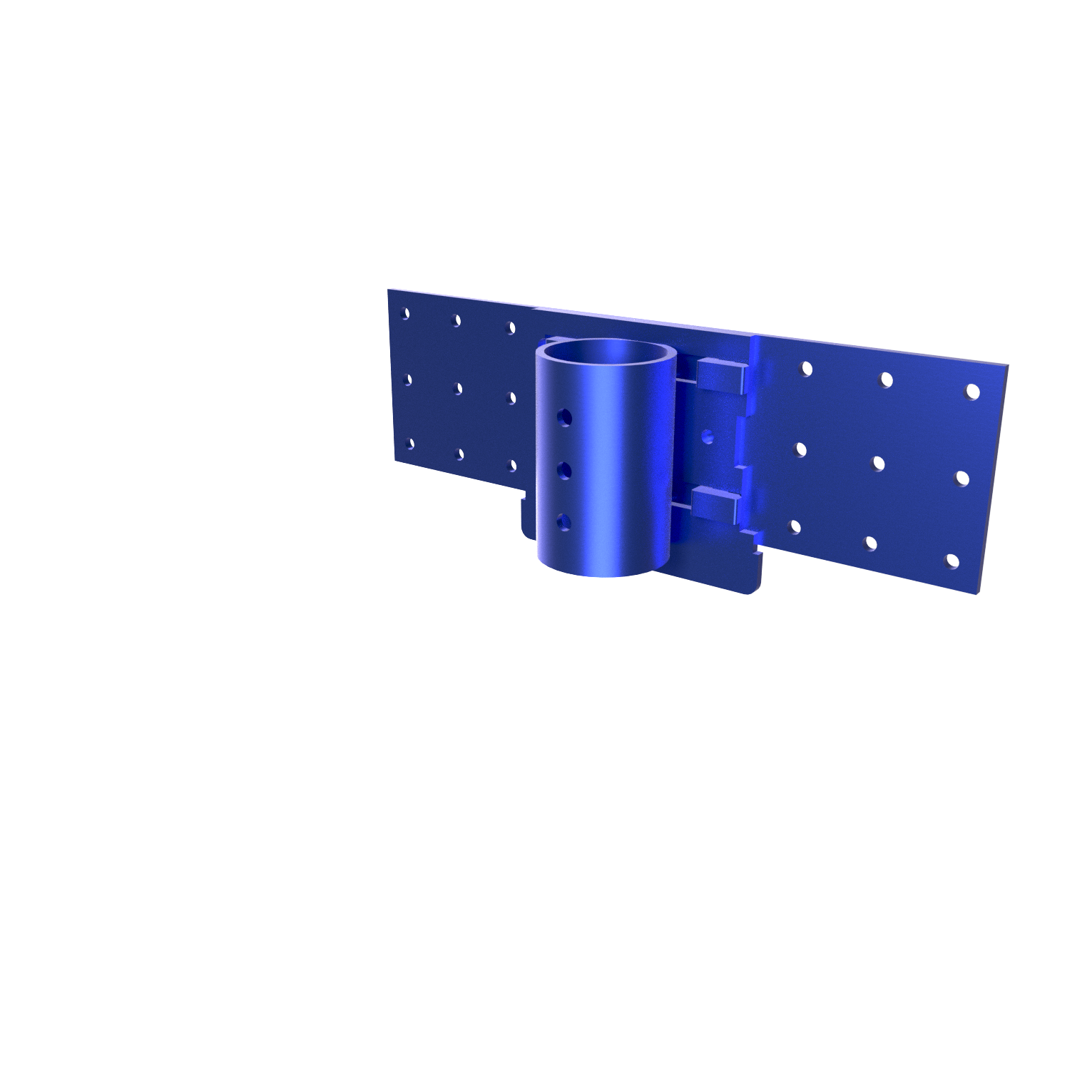

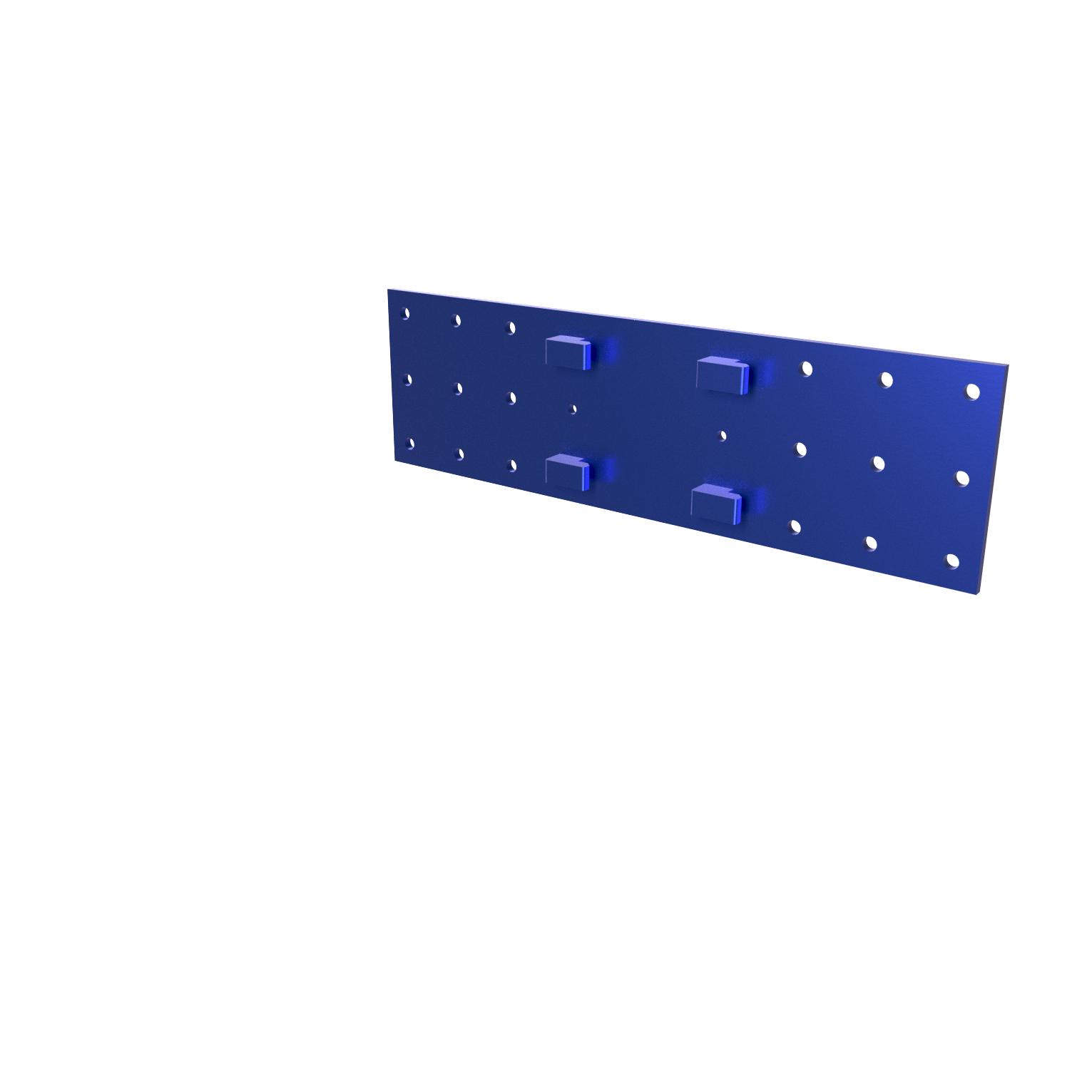

Micropile Bracket consists of a hinged collar tube with (3) 3/4˝ threaded bolt holes for connection to micropile casing. They include steel angle with thru holes for attachment to existing concrete using expansion anchors. The bracket also has integrated motor mount support points to easily align micropile placement. MAGNUM® products are manufactured in the USA according to our ISO 9001 approved quality program. MAGNUM® brackets are designed in accordance with ICC-AC358, IBC, ACI, and AISC codes. Design and detailing of the connection to the structure varies by project. It is the responsibility of the registered design professional including maximum concrete span, pier spacing, concrete shear, and concrete bearing.

Additional information

| Fits Steel Micropile Casings | 3", 3.5", 4", 4.5" |

|---|---|

| Allowable Compression/Tension (Tons) | |

| Allowable Compression/Tension (Kips) |

Description

Attach bracket plate to the side of existing foundation using up to (18) 1/2” concrete anchors. Attach drill support arms and mount drill. Drill micropile to the specified depth. Install desired reinforcing steel bar, grout and a 6ft minimum length section of casing at the top of the pile. Remove the drill and drill arms for use on the next micropile. Slip appropriate collar tube over the micropile casing and interlock tabbed connection, secure collar to plate with provided bolts. Once the micropile grout has cured a MAGNUM® ram or MAGNUM® lifting kit, with the appropriate sized shoe, can be used to life and relevel the structure if necessary. Lock-off the pile to the bracket with one, two or three 3/4” Grade 8 bolts, or weld. (Expansion Anchors Sold Separately)

*Bracket connection to pile consists of field threaded blind bolts as described in Section 7-13 of AISC Code. Capacities shown are based on IAS accredited laboratory testing of MAGNUM® products.