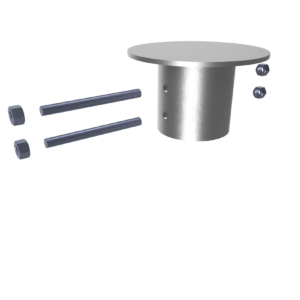

MHC1415-3O1010B Tilted Plate Cap Allowable Capacity 16 Tons

Magnum MHC1415-3O1010B bearing plate cap consist of a collar tube with bolt holes for connection to MAGNUM® helical piles and a circular bearing plate with an integrated nut. MAGNUM® products are manufactured in the USA according to our ISO 9001 approved quality program. Structural capacities are developed according to AISC 360 considering an average design life of 75 years for hot-dip galvanized steel in most soil conditions. Bare steel is available upon request. Design and detailing of the structure, to which bearing plate cap is attached varies by project. It is the responsibility of the registered design professional.

Additional information

| Allowable Compression/ Tension (Tons) | 16 Tons / 16 Tons |

|---|---|

| Ultimate Compression/ Tension (Tons) | 32 Tons / 32 Tons |

| Helical Pile Compatibility | https://www.magnumpiering.com/products/mh313b-helical-piles/ |

Description

Install a MAGNUM® Helical Pile to the correct depth, torque, and capacity. Cut-off the pile shaft at the proper elevation. Drill (1) 1-5/16” holes through the shaft using a MAGNUM® drill template. Place the cap over the shaft and secure with (1) 1-1/4” bolts. Snug tighten the nuts. Alternatively, drilling through pile may be omitted and plug welds may be used to secure cap to pile in place of bolt(s). See MAGNUM® Technical Bulletin TB004. Ensure direct bearing of plate on shaft. Affix the structure to the pile cap by installing a threaded rod through the connection point into the integrated nut in the cap. Connection to structures vary by project, tightness and fit-up requirements are the responsibility of the registered design professional.