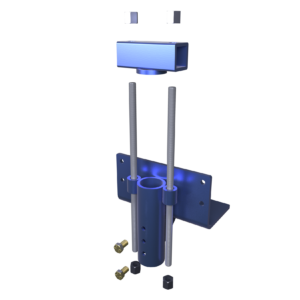

MP1030-150 Lifting Bracket Allowable Capacity 10 Tons

MP1030-150 Lifting Bracket consists of steel angle with a pair of gusset plates for connection to MAGNUM® Push Piers or Helical Piles via a pair of threaded rods and steel T-Beam. MAGNUM® products are manufactured in the USA according to our ISO 9001 approved quality program. MAGNUM® brackets are designed in accordance with ICC-AC358, IBC, ACI, and AISC codes. Design and detailing of the connection to the structure varies by project. It is the responsibility of the registered design professional including maximum concrete span, pier spacing, concrete shear, and concrete bearing

Additional information

| Configuration | 8˝ x 8˝ x 14˝ x 3/8˝ Plate with (4) 11/16˝ Thru Holes and 3” O.D. T-Pipe |

|---|---|

| Pier Size Compatibility |

Description

Prepare the existing foundation by chipping the footing (if applicable) flush with the foundation wall. Apply a grout bed of high-strength, fast-setting, non-shrink grout a minimum of 1/2" thick to the bottom angle face. Place the bracket on the foundation and attach with four 5/8˝ Hilti Kwik Bolt 3's (or equivalent). Excavate under the bracket at the pier location so the helix bearing plates fit below the existing foundation and the shaft is as close as possible to the face of the bracket. Install the helical pile at 3° from vertical to the correct depth and torque. Cut-off the helical pile shaft at 1" to 6" above the bracket gusset plates (as required for lifting). Connect the helical pile to the bracket by sliding the T-Pipe down the shaft; force the T-Pipe toward the bracket face and lock into position with the 5/8˝ hex bolt and nut provided. To lock-off the pile, simply tighten the two hex nuts located above the T-Pipe. Otherwise, use Magnum® MP1031 Lifting Accessory to pre-load the pile to specific pressure and/or to lift the foundation.