MP1039-3 Pin Bracket Allowable Capacity 25 Tons

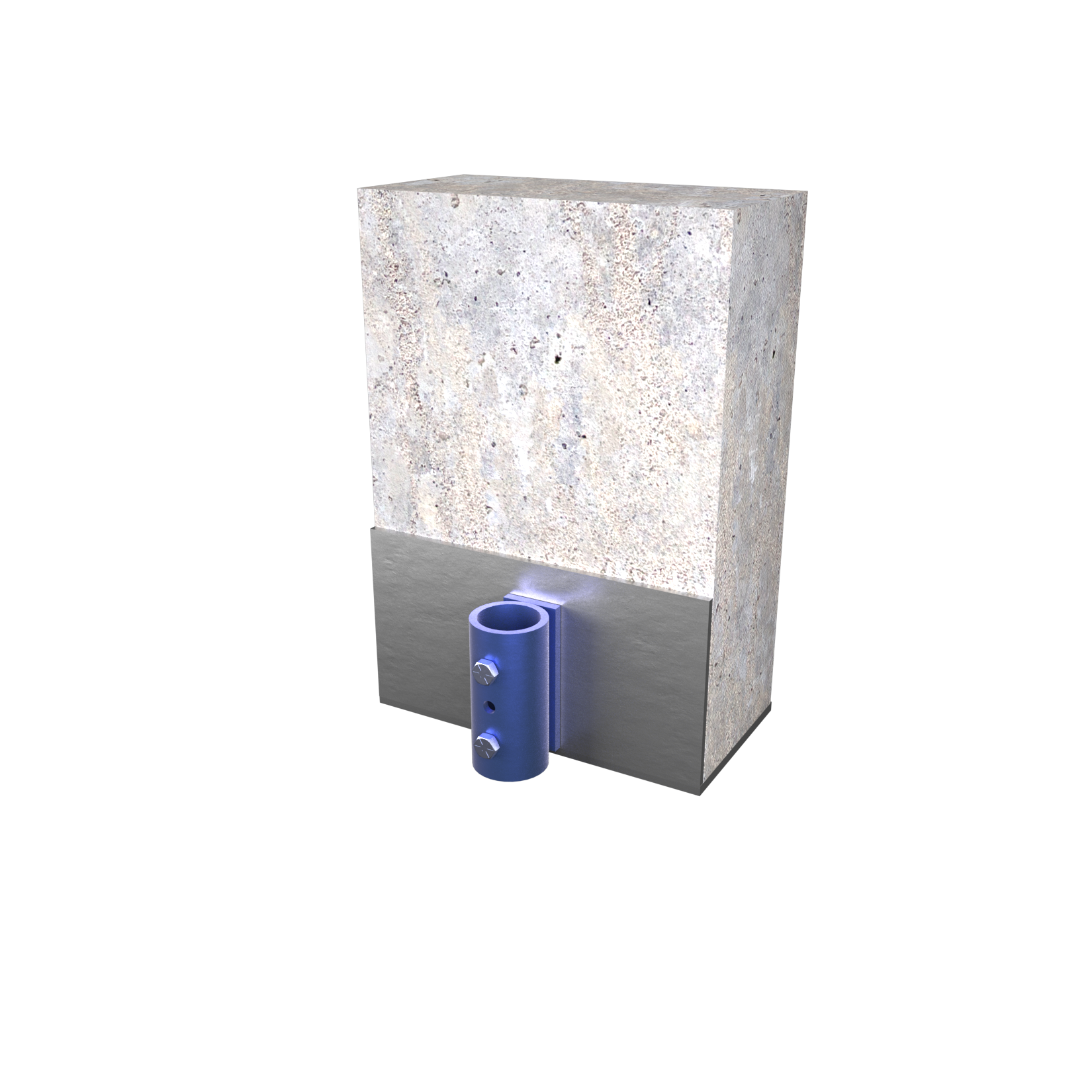

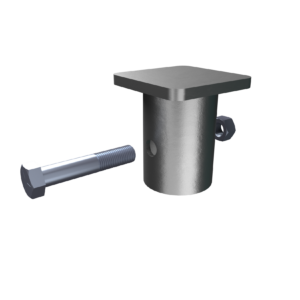

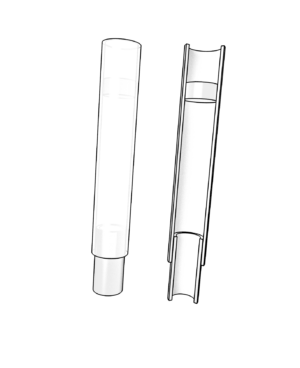

MP1039-3 Pin bracket consists of a collar tube with (3) 3/4˝ threaded bolt holes. This connects to the MAGNUM® helical piles and push piers and steel plate for welded attachment to existing steel. MAGNUM® products are manufactured in the USA according to our ISO 9001 approved quality program. MAGNUM® brackets are designed in accordance with ICC-AC358, IBC, ACI, and AISC codes. Design and detailing of the connection to the structure varies by project. It is the responsibility of the registered design professional including weld to existing steel, maximum concrete span, pier spacing, concrete shear, and concrete bearing.

Additional information

| Connection Type | |

|---|---|

| Allowable Capacity (ton) by Connection Type | 5 Tons, 8 Tons, 14 Tons |

| Ultimate Capacity (ton) by Connection Type | 10 Tons, 17 Tons, 28 Tons |

| Configuration | |

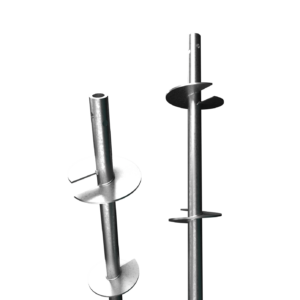

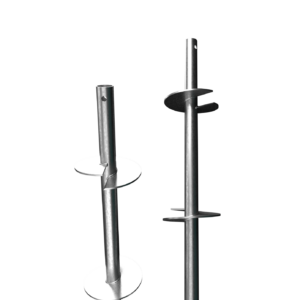

| Pile Compatibility | https://www.magnumpiering.com/products/mh313b-helical-piles/ |

Description

Prepare the existing foundation. For steel push pier applications, prepare the structural steel for welding. Attach the bracket and MAGNUM® ram. Install the push pier to the required pressure and load test. For helical pile applications, pot-hole excavate the pile location so the helix bearing plates fit below the existing foundation. The shaft should be as close as possible to the face of the foundation. Install the helical pile to the correct depth and torque. Prepare the structural steel for welding, then mount the bracket and install the sleeve. In both cases, lift the structure as needed using either a MAGNUM® ram or lifting fixture. Drill holes and bolt the bracket to the pile.