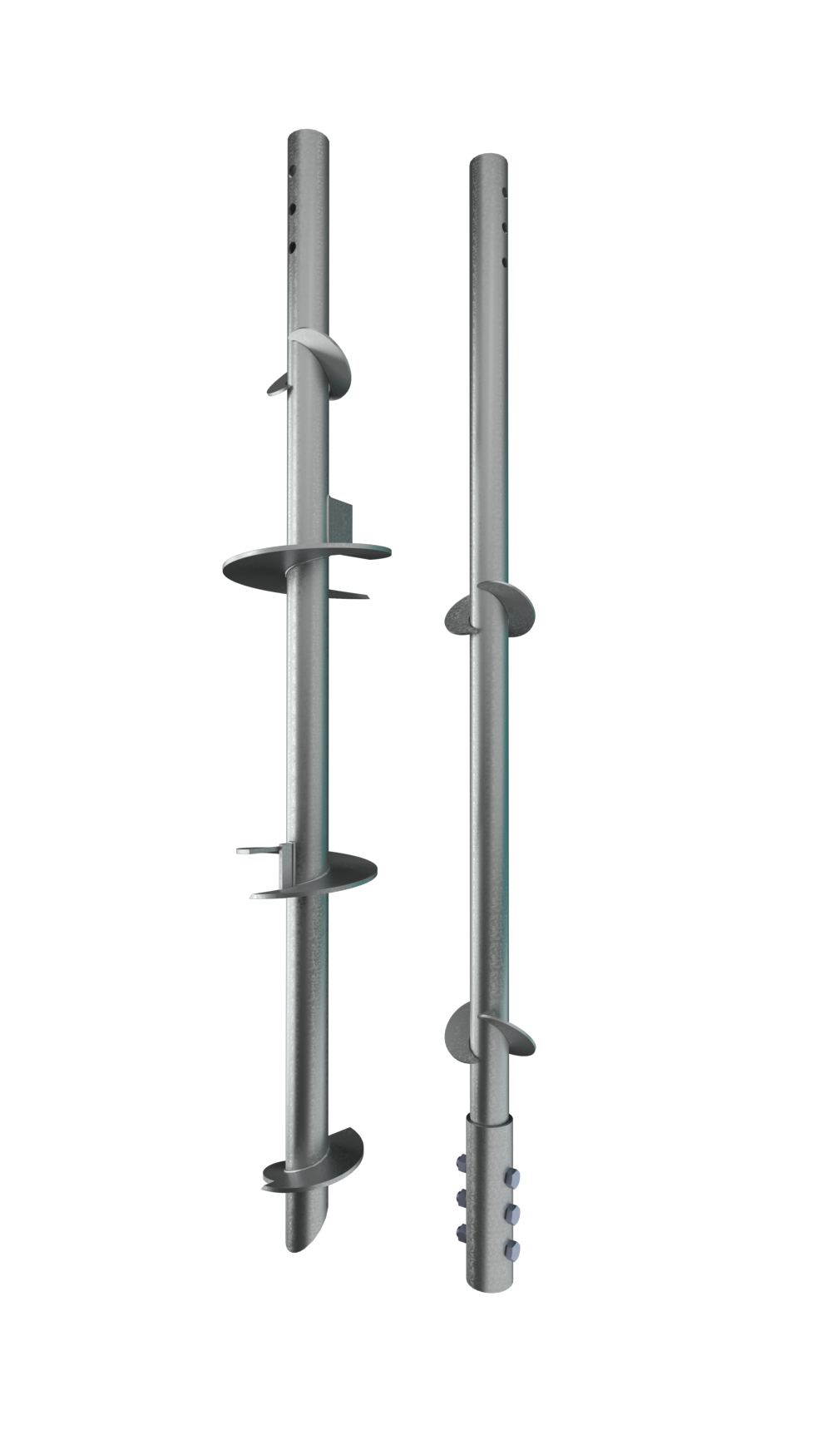

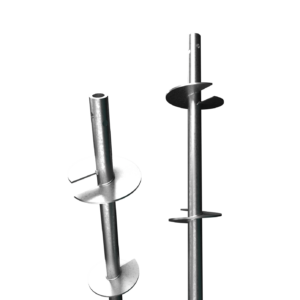

MAGNATUDE® MG542Y-6 Propulsion Grout Piles Allowable Capacity 195 Tons

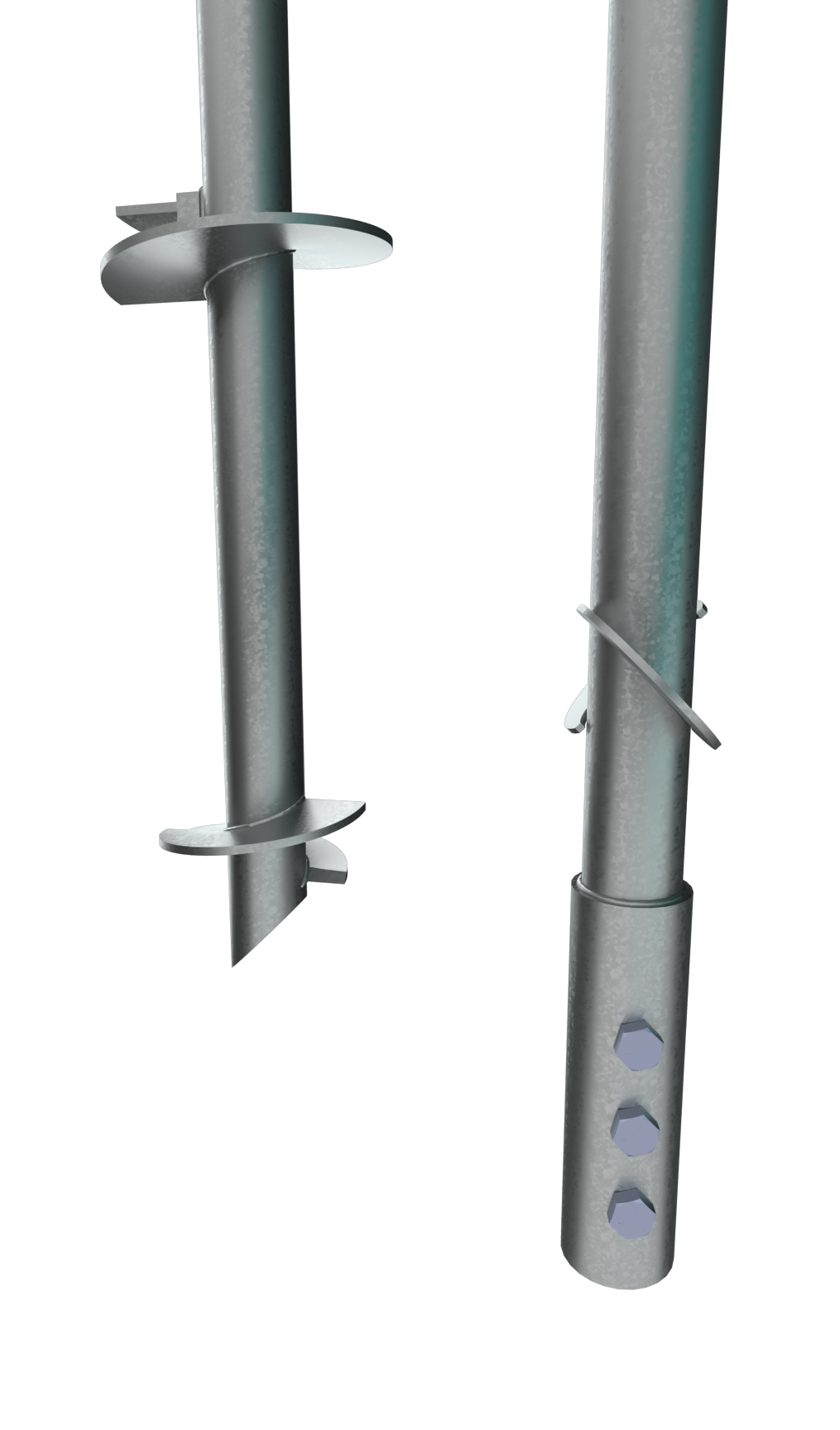

MAGNATUDE® propulsion grout piles combine the unique benefits of helical installation with grouted displacement piles. MAGNUM® products are manufactured in the USA according to our ISO 9001 approved Quality Program. Our MAGNATUDE® piles utilize rigid bolted couplings to join extension sections and the lead section. This extends the grout column and placing the helical bearing elements down to the desired bearing stratum. Structural capacities are developed according to AISC 360 and consider buckling length of 5 ft unbraced length. Grout displacement plates create an annular space which is filled by grout that is propelled down from the grout reservoir at the surface by the grout propellers that are spaced along the pile shaft. Grout is relied upon for ground improvement, adhesion and corrosion protection only. Required depth of the pile depends on ground conditions and should be determined for each site by a design professional.

Additional information

| Allowable Compression/ Tension (Tons) | 195 Tons / 141 Tons |

|---|---|

| Ultimate Compression | 325 Tons |

| Grout Column | 14 in. Diam. |

Description

Begin by auguring a grout reservoir and fill with high-mobility neat cement or sanded grout. Case reservoir if needed to prevent caving and water intrusion. Install MAGNATUDE® propulsion grout piles through the reservoir. Displacement plates clear a path for the grout column. Propellers force grout to follow. Apply crowd and torque as needed to advance pile. Continuously supply grout to reservoir. Add extensions to reach required depth. Monitor and maintain position and desired inclination.